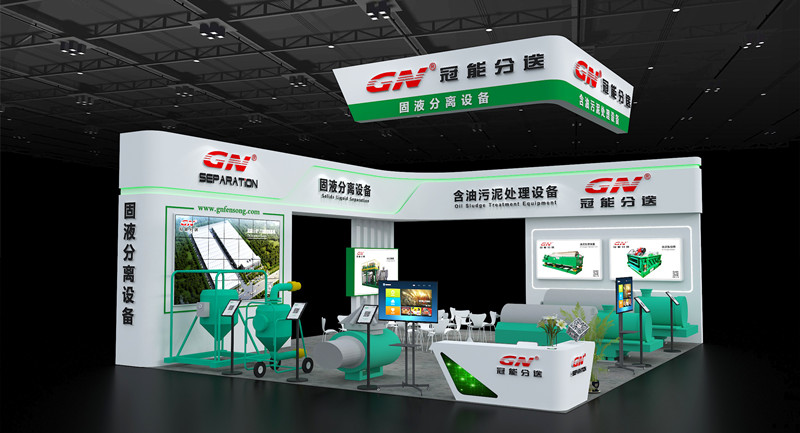

GN Separation has effectively supplied a 5m3 oily sludge treatment system recently to a client located in the Middle East. This system is tailored to efficiently manage and extract valuable constituents from the residuals of oil sludge treatment extraction. This delivery signifies another stride in GN’s endeavors to broaden its footprint in global markets, furnishing solutions that uphold both ecological responsibility and resource reclamation.

The system comprises four key components: a premixing tank, the GNZS706 fine Shale Shaker, the GNLW364 three-phase decanter centrifuge, and a containerized chemical dosing system. Each element plays an indispensable role in the system’s functionality, offering crucial processing capabilities across various phases of sludge treatment.

At the onset of the process, the premixing tank readies the oily sludge by blending and homogenizing it, ensuring effective segregation of its constituents. This initial step is pivotal for facilitating the subsequent mechanical separation carried out by the GNZS706 fine shale shaker, streamlining the removal of larger particulate matter and thereby alleviating the burden on subsequent separation stages.

The nucleus of the system, the GNLW364 three-phase decanter centrifuge, assumes control to precisely partition the sludge into oil, water, and solids. Leveraging its high-speed rotational capacity and advanced design, the centrifuge attains remarkable separation efficiency, critical for optimizing oil retrieval and curbing residual waste.

Wrapping up the configuration, the containerized chemical dosing system administers specific chemicals required to dismantle emulsions in the sludge, augmenting separation quality and enhancing the purity of the extracted oil and water.

This installation not only underscores GN Separation’s dedication to furnishing high-caliber environmental solutions but also enhances the operational prowess of its clients within the oil and gas realm. The system’s capacity to enhance oil recovery rates and mitigate environmental repercussions delivers significant value to regions grappling with the complexities of managing by-products from the oil industry.

For further insights into GN Separation’s array of products and their versatile applications, please visit GN Separation Equipment Co., Ltd.