GN Separation has emerged triumphant from the recently concluded Aisawater 2024 exhibition in Malaysia, marking a significant milestone in its journey of innovation and global expansion. Continue reading

Introduction of no-load test run for decanter centrifuge

The no-load test run for decanter centrifuge is a necessary step for the inspection of decanter centrifuge. The introduction below is recommended by GN Separation.

GN 5m3 Oily Sludge Treatment System for Middle East Customer

GN Separation has effectively supplied a 5m3 oily sludge treatment system recently to a client located in the Middle East. This system is tailored to efficiently manage and extract valuable constituents from the residuals of oil sludge treatment extraction. This delivery signifies another stride in GN’s endeavors to broaden its footprint in global markets, furnishing solutions that uphold both ecological responsibility and resource reclamation.

The system comprises four key components: a premixing tank, the GNZS706 fine Shale Shaker, the GNLW364 three-phase decanter centrifuge, and a containerized chemical dosing system. Each element plays an indispensable role in the system’s functionality, offering crucial processing capabilities across various phases of sludge treatment.

At the onset of the process, the premixing tank readies the oily sludge by blending and homogenizing it, ensuring effective segregation of its constituents. This initial step is pivotal for facilitating the subsequent mechanical separation carried out by the GNZS706 fine shale shaker, streamlining the removal of larger particulate matter and thereby alleviating the burden on subsequent separation stages.

The nucleus of the system, the GNLW364 three-phase decanter centrifuge, assumes control to precisely partition the sludge into oil, water, and solids. Leveraging its high-speed rotational capacity and advanced design, the centrifuge attains remarkable separation efficiency, critical for optimizing oil retrieval and curbing residual waste.

Wrapping up the configuration, the containerized chemical dosing system administers specific chemicals required to dismantle emulsions in the sludge, augmenting separation quality and enhancing the purity of the extracted oil and water.

This installation not only underscores GN Separation’s dedication to furnishing high-caliber environmental solutions but also enhances the operational prowess of its clients within the oil and gas realm. The system’s capacity to enhance oil recovery rates and mitigate environmental repercussions delivers significant value to regions grappling with the complexities of managing by-products from the oil industry.

For further insights into GN Separation’s array of products and their versatile applications, please visit GN Separation Equipment Co., Ltd.

Trouble Shooting Of Decanter Centrifuge Gear Box

Common failures of Decanter centrifuge gear boxes include tooth surface wear, tooth surface gluing and abrasions, tooth surface contact fatigue, bending fatigue and broken teeth. The causes are manufacturing errors, poor assembly, poor lubrication, overload, and operational errors. Due to the characteristics of the structure and working principle of the gear, its vibration signal is very complicated, and the vibration fault diagnosis of it needs to be analyzed in both the time domain and the frequency domain. Whether the gear is in a normal or abnormal state, the frequency of gear meshing stiffness always exists.

Therefore, the gearbox should be diagnosed based on the gearing frequency component of the gear. Due to the complexity of the gear signal, the fault has many effects on the vibration signal, especially due to the effect of amplitude modulation and frequency modulation, there are many sideband structures on the vibration spectrum of the gear, which requires specific analysis during the analysis and diagnosis Components to achieve accurate diagnosis of gearbox faults.

The characteristic frequency of the Decanter centrifuge gear box failure is as follows:

1. The normal frequency spectrum shows the 1X and meshing frequencies of all the rotating shafts. There are speed sidebands on both sides of the gear meshing frequency, and the peak value is small.

2. Gear wear. The natural frequency of the gear appears, and there is a speed sideband of the shaft where the worn gear is located. When the wear is obvious, a higher peak sideband will appear near the meshing frequency.

3. Decanter centrifuge gear eccentricity. There is a sideband of higher amplitude near the meshing frequency, indicating that the gear is eccentric or the shaft is not parallel, and the peak of the meshing frequency increases with the increase of the load.

4. The decanter centrifuge gears are misaligned. The vibration of the second or higher harmonics of the meshing frequency is almost always excited, and the peak value at the 2X or 3X meshing frequency spectrum line is large, and there is a side frequency of the rotation frequency interval.

Stack Vibrating Screen for China Shanxi Coal Mining Company

GN Separation recently accomplished a noteworthy achievement with the successful production completion of a new batch of high-frequency stack vibrating screens, meticulously crafted for application in coal mines situated within the Shaanxi province. This development signifies a significant technological leap in the coal mining sector, as these stack vibrating screens are specifically engineered to optimize the separation of coal particles, thereby revolutionizing fine coal recovery processes while concurrently reducing waste production.

The distinguishing features of GN’s high-frequency stack vibrating screens greatly contribute to their unparalleled performance and efficiency. Foremost, the stacked design of these screens offers a myriad of advantages, notably enabling a more compact footprint. This streamlined design not only reduces the space required for installation but also facilitates seamless operation within the confines of space-constrained mining environments, which are prevalent in many coal mines across the globe.

Furthermore, GN’s vibrating screens incorporate cutting-edge technology to ensure impeccable performance and reliability. By leveraging high-quality excitation motors such as Martin or OLI motors, these screens are engineered to deliver extended periods of uninterrupted service, thereby bolstering continuous production processes while simultaneously minimizing downtime – a critical factor in maintaining operational efficiency within coal mining operations.

Moreover, the inclusion of a polyurea resin coating in the construction of these screens provides unparalleled resistance to abrasion and corrosion, thus guaranteeing sustained performance and durability even under the most demanding operating conditions. Additionally, the implementation of a unique polyurethane screen mesh further enhances the screens’ durability and flexibility, facilitating effective screening of materials and minimizing instances of blockages, thereby maximizing throughput and ultimately resulting in heightened recovery rates and superior product quality.

In addition to offering vibrating screens tailored for the mining sector, GN Separation also provides an extensive range of complementary solutions, including dewatering centrifuges designed specifically for coal slime suspension dewatering applications, thereby further enhancing its comprehensive suite of offerings for the mining industry.

For comprehensive details regarding GN Separation’s mining vibrating screens and accompanying solutions, we invite interested parties to reach out to us directly, where our team of experts stands ready to provide tailored assistance and support.

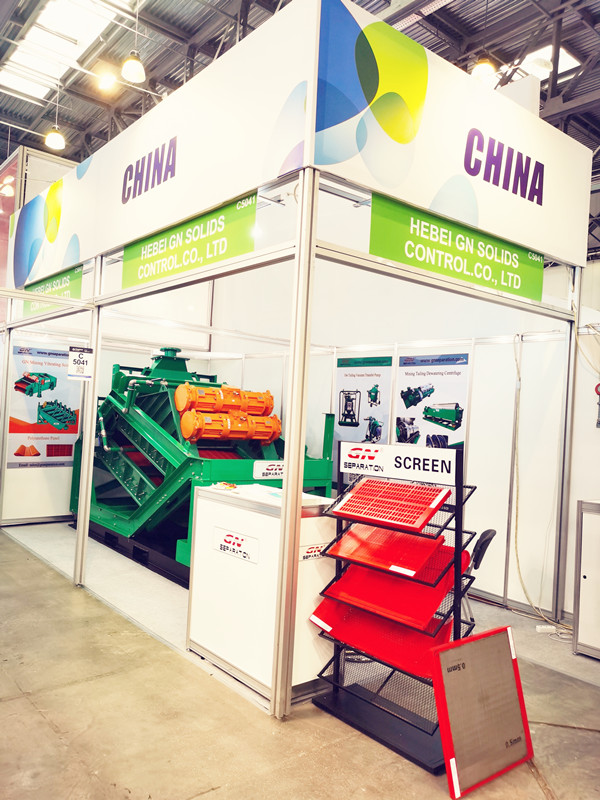

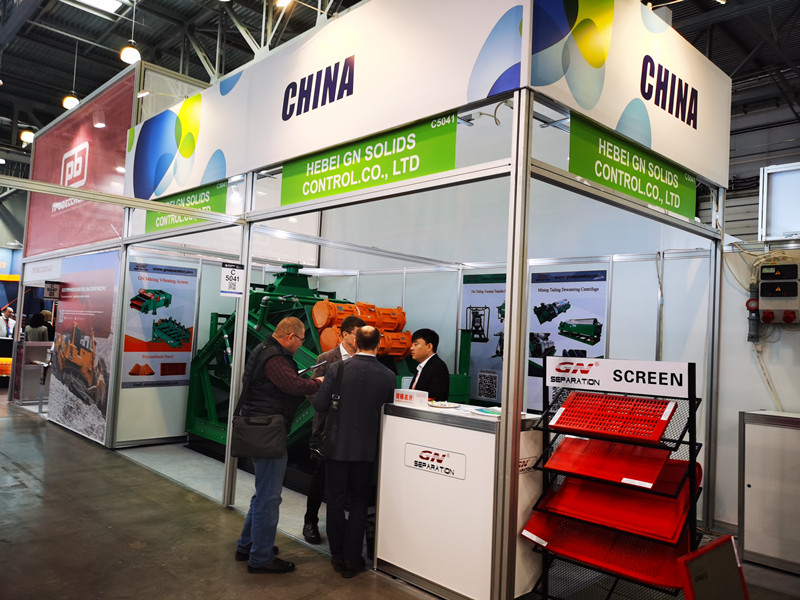

GN Separation will Attend MiningWorld Russia 2024 in April

Miningworld Russia is an international exhibition showcasing machinery and equipment for mining, processing, and transportation of minerals. GN Separation made its debut at this event in 2023 and achieved significant results. This year, GN is returning to participate, aiming to engage in business negotiations with both new and existing customers during the exhibition.

Event Name: Miningworld Russia

Event Date: April 23rd to 25th, 2024

Event Venue: Crocus Expo, Pavilion 1, Moscow, Russia GN Booth: B5001, Hall 2

As a specialized manufacturer of screening equipment for mines, GN Separation possesses extensive research and development experience along with modern intelligent technology. The company offers a range of efficient screening equipment, including linear motion dewatering vibrating screens, high-frequency stacked screens, and large banana screens. Here’s a detailed overview of the characteristics and applications of these three screening equipment types:

Medium-sized linear vibrating screen

GN’s linear vibrating screen boasts excellent design and stable performance. It finds wide applications in desliming, dewatering, media removal, and tailings dry discharge treatment across materials such as iron ore, non-ferrous metal ore, and coal mines. Notable advantages include efficient dewatering, a robust structure, wear resistance, corrosion resistance, and flexible customization options.

High-frequency stack vibrating screen

GN’s high-frequency stack vibrating screen is popular for its stacked design and efficient screening efficiency. Its surface is coated with polyurea resin for enhanced wear and corrosion resistance. The stack-layered design optimizes material collection, reduces floor space, and enhances space utilization. Additionally, high-frequency vibration effectively prevents sieve hole blockage, thereby improving screening efficiency.

GN’s large banana vibrating screen is primarily used for dry or wet classification, desliming, and media removal processes. Key features include forced synchronization, efficient classification, and strong adaptability.

In summary, each type of GN vibrating screen offers unique characteristics to meet diverse screening needs in different mining applications. GN looks forward to meeting you at the exhibition.

GN Separation is to Kick off Its Innovative 3-phase Decanter Centrifuge at CIPPE

At the upcoming China International Petroleum and Petrochemical Technology and Equipment Exhibition (CIPPE), GN separation, a professional separation technology provider, will showcase its innovative 3-phase decanter centrifuge.

Show Name: CIPPE (short for China International Petroleum & Petrochemical Technology and Equipment Exhibition)

Date:March 25~27, 2024

Venue:New China International Exhibition Center, Beijing

GN Booth No.: E2168

GN 3-phase decanter centrifuge has attracted the attention of many industries with its excellent performance and unique design. Its bowl are made of duplex stainless steel 2205, and the use of centrifugal casting technology ensures the compactness of the material composition, thus achieving excellent dynamic balance performance, which is crucial for high-speed and stable operation. At the same time, the components that directly contact the processing materials are made of 316L stainless steel, ensuring the durability and corrosion resistance of the machine.

The design of this centrifuge is to efficiently separate heavy liquid phase, light liquid phase and solid residue. It uses the density difference between different materials to achieve 3-phase separation. This function benefits from the diversified centrifugal force generated by the machine, making the separation of various components more precise. The centripetal pump design adopted by the centrifuge achieves precise control over the boundaries of different liquid phases within the device, thereby meeting various separation requirements and ensuring clarity after fluid separation.

It is worth mentioning that the GN 3-phase decanter centrifuge is also equipped with a frequency conversion control cabinet, which can achieve precise control of the centrifuge’s rotational speed and feed rate by adjusting the speeds of the main motor, auxiliary motor, and feed pump. This advanced feature gives the machine high flexibility, allowing it to adapt to various complex operating scenarios.

In terms of application fields, 3-phase decanter centrifuges have broad application prospects in oil sludge treatment systems, edible oil extraction, and kitchen waste management. GN Separation is constantly meeting the growing needs of the industry by relentlessly pursuing innovative technologies and product quality.

We sincerely invite all enterprises and individuals interested in separation technology to visit the GN booth during the CIPPE exhibition to experience the powerful functions of the 3-phase decanter centrifuge and discuss future cooperation opportunities. We believe that through this exhibition, GN will continue to consolidate its leading position in the field of separation technology and contribute more to the sustainable development of the industry.

GN Separation will attend IE Expo China 2024 in Shanghai

GN Separation is excited to announce its participation in the IE Expo in Shanghai next month, and cordially invites friends, customers, and industry colleagues to visit the GN booth to explore GN’s innovative products and engage in technical and commercial discussions.

Show Details:

- Show Name: IE Expo China 2024

- Location: Shanghai New International Expo Centre (SNIEC)

- Expo Date: April 18~20, 2024

- GN Booth: N4-H46\I46 (Hall 4)

During the expo, GN will showcase some of its main industrial separation and conveying equipment. Here’s a brief overview of GN’s featured products:

Sludge Dewatering Centrifuge:

GN will exhibit the GNLW554 model with a 22-inch bowldewatering decanter centrifuge. This high-speed rotating bowl utilizes centrifugal force to efficiently separate solids and liquids based on their different densities. Additionally, GN will showcase the GNLWS364 model, a 3-phase decanter centrifuge suitable for separating light liquid, heavy liquid, and solids. To enhance durability, GN utilizes tungsten carbide plates and bushings for screw blade and solids discharging port protection, thereby extending the machine’s service life.

Disc Stack Separator:

The disc stack separator, also known as a disc stack centrifuge, operates at higher speeds compared to decanter centrifuges. It is typically installed after the decanter centrifuge to separate ultra-fine solids that cannot be removed by the decanter. With the ability to generate higher centrifugal force, the disc stack separator is ideal for slurry clarifying and oil-water separation. GN emphasizes the importance of maintaining slurry feed with solids concentrations below 5% to prevent blockages and ensure smooth operation.

Solid Vacuum Pump:

GN will showcase two models of solid vacuum pump: GNSP40 and GNSP10, each offering different capacities and designs. All models feature a compact structure for easy onsite layout, with the GNSP10 model equipped with wheels for convenient mobility. These pumps operate automatically with preset suction and discharging times, while the GNSP40 model also offers manual operation. Suitable for various material transfers, including high fluidity liquids, low fluidity slurries, and solid powders and gravels, the solid vacuum pump is fully pneumatic-driven for efficient operation.

GN eagerly anticipates meeting you at IE expo China 2024 and looks forward to fruitful discussions and collaborations.

Leading the New Chapter of Offshore Drilling: GN High-G Dry Shale Vibrating Screen System Gets Ready to Go

With the continuous advancement of technology, offshore drilling projects have ushered in a new milestone. GN recently announced that a series of high-G dry shale vibrating screen systems have been manufactured and are ready to be used in offshore drilling projects for the treatment of water-based cuttings.

This complete set of systems includes four sets of high-G dry shale vibrating screens, mud tanks, centrifugal pumps, mud agitators, and intelligent control systems. Each component has been carefully designed and manufactured to ensure stable operation in complex offshore environments and efficient processing of cuttings generated during drilling.

GN Solid Control, as a leading brand in mud solid control systems and drilling waste management, has always been committed to providing customers with excellent products and services. We are deeply aware of the uniqueness of each drilling project and are dedicated to providing comprehensive one-stop solutions to meet the needs of various mud recovery projects.

For GN, ensuring the optimal performance and long-term operational efficiency of drying and dehydration systems is crucial. Our technical, production, and quality control departments strictly supervise material selection, preparation, and all aspects of the production process, conducting thorough inspections at each stage. This meticulous attention to detail ensures the reliability and lifespan of our equipment components, guaranteeing seamless long-term operation.

If you need any assistance in operating and maintaining GN’s equipment, such as high-G dry shale vibrating screens, mud tanks, centrifugal pumps, or mud agitators, please feel free to contact our company. Our experienced engineering team possesses profound expertise in related industries and is ready to provide comprehensive support based on your specific needs. By cultivating partnerships, we strive to promote the success of your projects and foster stable and lasting collaborative relationships. In addition, we provide support through online assistance and on-site guidance to address any unique situations that may arise.

As a leading manufacturer of separation equipment and transportation solutions, GN prioritizes product quality and its enduring benefits for users. Furthermore, we pride ourselves on our specialization in the field of decanter centrifuges. GN carefully selects high-quality raw materials and employs superior centrifugal casting or forged stainless steel materials. Additionally, we provide hard alloy protection for wear parts, ensuring robust performance and lifespan.

Looking ahead, GN will continue to uphold the spirit of innovation, continuously optimizing product performance and service quality, and providing more efficient and reliable equipment support for offshore drilling projects. We firmly believe that through our efforts, we will drive the continuous development of offshore drilling technology, bringing more innovations and breakthroughs to the industry.

GN Solid Vacuum Pump Inventory Meets Customer Fast Delivery Demand

GN Separation has recently announced a significant update regarding its inventory of Solid Vacuum Pumps, including models GNSP10B, GNSP20B, and GNSP40B. This strategic stock enhancement is poised to meet the rapidly growing demand for fast deliveries among its clientele, ensuring that businesses can maintain uninterrupted operations.

We are excited to announce a significant update regarding our inventory of Solid Vacuum Pumps at GN Separation, particularly models GNSP10B, GNSP20B, and GNSP40B. This strategic enhancement of our stock is aimed at meeting the increasing demand for fast deliveries among our clientele, ensuring uninterrupted operations for businesses.

GN Separation‘s Solid Vacuum Pumps are designed to cater to a wide range of industrial applications, including environmental protection, mining, and wastewater treatment. Our latest models, GNSP10B, GNSP20B, and GNSP40B, are tailored to different operational scales, offering solutions for businesses of any size. For instance, the GNSP10B model is ideal for smaller-scale operations requiring mobility and efficiency, while the GNSP40B model is suitable for larger, more demanding projects that involve substantial volumes of solid waste or materials.

The decision to bolster our inventory levels is a response to the industry’s demand for reliable and swift delivery of critical equipment. With these models readily available, GN Separation reaffirms its commitment to supporting our customers’ operational needs promptly. This readiness not only showcases our understanding of market demands but also underscores our dedication to providing high-quality solutions without delay.

Furthermore, our Solid Vacuum Pumps are renowned for their robust design, energy efficiency, and ease of operation, contributing to lower operational costs and a more environmentally friendly footprint. These features align with the industry’s push towards sustainable practices.

Customers interested in GN Separation’s Solid Vacuum Pumps can now expect faster delivery times, thanks to our proactive approach to inventory management. This development is particularly beneficial for businesses aiming to minimize downtime and expedite project completion.

We believe that this announcement will be well-received by the industry, reflecting GN Separation’s ongoing commitment to customer satisfaction and our ability to anticipate and meet market needs efficiently.

For more information on GN Separation’s Solid Vacuum Pumps, including detailed product specifications and applications, please visit our website.